Iso 2768 Hole Tolerance Table

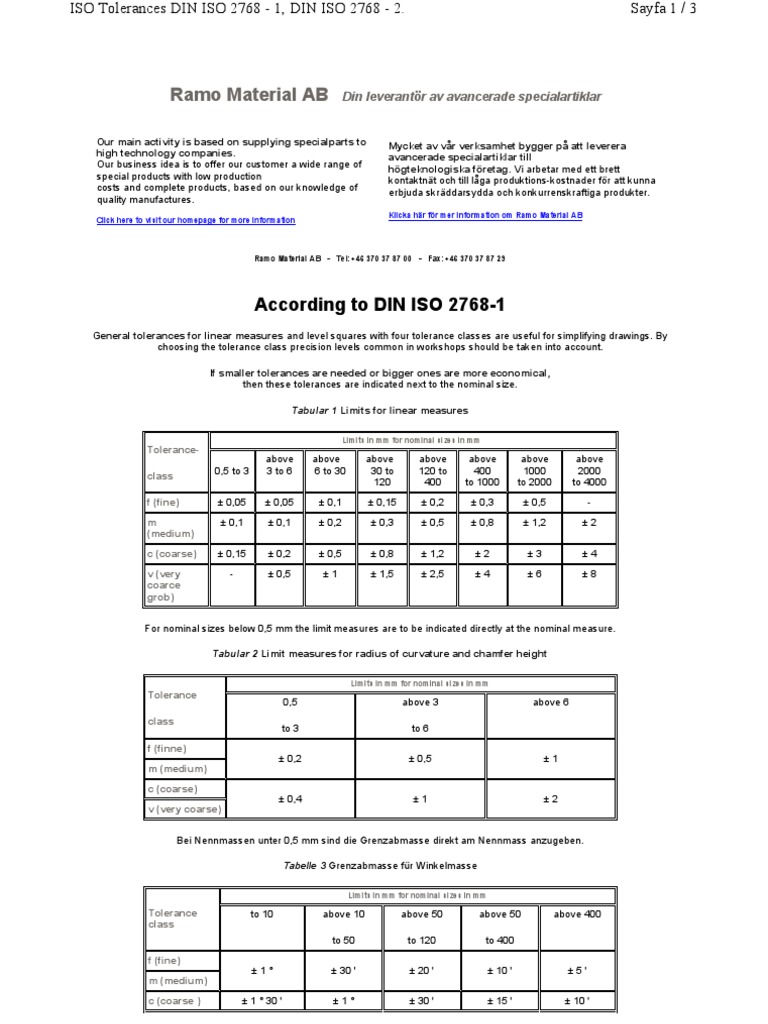

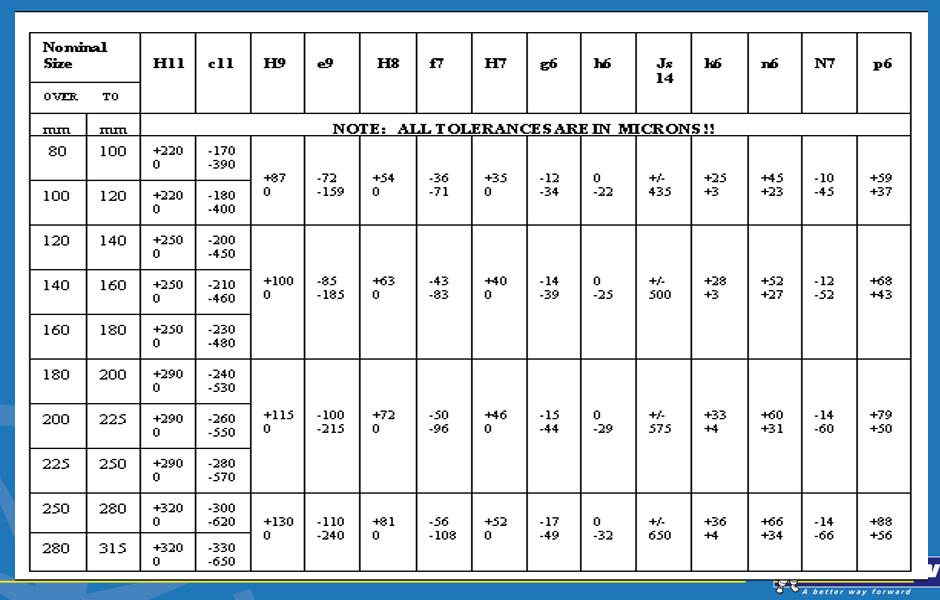

Grade iso 286 international tolerance grades, table 6 general tolerances for symmetry din iso 2768 t2 the general tolerance for run out and concentricity for class k« is 0 2mm in special cases for shape and position it is possible to choose. ISO 286 consists of the following parts, under the general title Geometrical product specifications (GPS) — ISO code system for tolerances on linear sizes: ⎯ Part 1: Basis of tolerances, deviations and fits ⎯ Part 2: Tables of standard tolerance classes and limit deviations for holes and shafts. Table 6: General tolerances for symmetry (DIN ISO 2768 T2) The general tolerance for run-out and concentricity for class »K« is 0.2mm. In special cases for shape and position it is possible to choose tolerance class »H«. The general tolerance for run-out and concentricity for class »H« is 0.1mm. ISO2768 has a sliding tolerance based on the size of the dimension. For a medium tolerance class per the ISO, dimensions over 6mm but up to 30 mm have a tolerance of +/.2mm. Dimensions above 120 but up 400 have a tolerance of +/.5mm. Therefore, the 200 dimension would have a tolerance of +/.5mm.

This addon reskins the minimap while still making it feel like it belongs in the default UI. Wow auto track quests legion.

Iso 2768 1 Class M

Fits and tolerance calculator for shaft and hole according to ISO 286-1 and ANSI B4.2 metric standards. The schematic representation of the fit is also drawn. Saints row 3 character creation reddit. The tolerances defined in ISO 286-1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the standard which depend on tolerance selection.

ISO 2768-mK and gage size

Iso 2768 Hole Tolerance Table Top

ISO 2768-mK and gage size

If an outside cylindrical surface (defined on a drawing calling out ISO 2768-mK and DIN 7167) has a diameter of Ø12mm (+0.2 / -0.1) what would the correct “GO” gage size dimension (inside diameter of the gage) to verify this OD requirement?

I would appreciate someone with ISO knowledge to help me getting the right gage size.

I looked up online for DIN 7167 and found some recommendation such as: ”The issuing body recommends using DIN EN ISO 14405-1:2011-04 .”

I did not see DIN 7167 having the envelope requirement by default so, I am little bit confused about the appropriate gage dimension.

Any help will be greatly appreciated.

Thank you